Premium

Advanced Synthetic Underlayment

A preferred alternative to traditional organic felt, TUFFDRY nail-down synthetic underlayment for sloped roofs has industry leading tear resistance, is lightweight and has a superior walkable surface.

Why is synthetic underlayment the top pick for roofers everywhere ?

Synthetic roofing underlayment emerged in the early 2000s, offering a better alternative to traditional asphalt based and organic felts/paper. Synthetic offers superior strength, 5x longer durability, better water-resistance, and comes as a lighter weight product that is easier, safer and faster during installation.

Synthetic underlayment is installed beneath the decorative roof covering (typically asphalt shingles, tiles or metal) and serves as a secondary barrier against water intrusion. It provides crucial backup protection, and is designed to work in tandem with the roof covering to create create a comprehensive system to keep water out and protect the integrity of a roof over time.

Its primary purposes include:

Acting as a temporary water barrier during roof installation, prior to the installation of the primary roof covering

Protecting the roof deck from moisture if the roof covering is ever damaged or compromised (e.g., missing shingles or cracked tiles).

Offering temporary water protection during construction or delays in roof installation.

Adding an extra layer of moisture resistance to reduce the risk of leaks caused by wind-driven rain or ice dams.

What Makes Synthetic Underlayment a Game-Changer?

1. Built Tough for the Long Haul

Unlike traditional felt, synthetic underlayment doesn’t break down as quickly under harsh weather conditions or UV exposure. It’s a material you can trust to hold up over time, keeping roofs protected longer.

2. Water-Resistant Protection

Synthetic underlayment is able to repel moisture better than all standard felt. This makes it a smart choice for homes in hail-prone and rainy regions, giving extra peace of mind against leaks.

3. Lightweight and Easy to Install

Roofing is hard work, but synthetic underlayment makes life a little easier. Its lightweight design is simple to roll out, and it lays flat on the roof deck, speeding up shingle installation while reducing frustration on the job site.

4. Slip-Resistant for Better Safety

Safety on the roof is critical, and synthetic underlayment delivers. Its slip-resistant surface offers better footing, even on steep pitches, making it a safer choice for roofers navigating tricky spots.

How to Select the Right Underlayment for Your Job ?

Not all underlayment is created equal, and the best choice depends on factors like the roof covering, climate, building codes, and project needs. Here is a step-by-step guide to selecting the right underlayment:

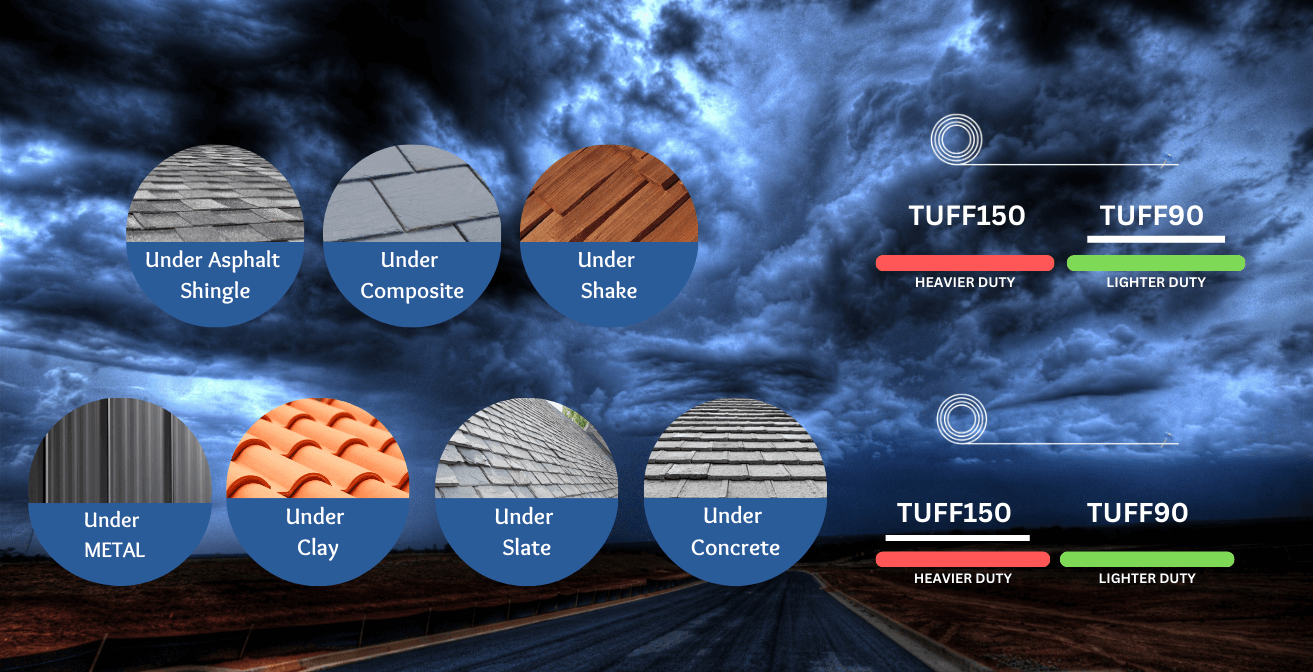

Match the Underlayment to the Roof Covering

Asphalt Shingles: Synthetic underlayment like TUFF90 is ideal for light weight asphalt shingles, due to its durability, slip resistance, and water resistance.

Tile or Slate Roofing: Look for heavier premium synthetic underlayment like TUFF150 that is built to withstand the additional friction and weight with heavier tiles.

Metal Roofing: Use peel and stick underlayment that will provide sound dampening as rain drops on a metal roof can be quite loud. Also look for underlayment with high-temperature resistance of at least 240deg (less critical as modern metal roofs are treated to avoid extreme heat transfer) as per your local building codes.

Consider Climate and Environmental Factors

The local climate significantly impacts the type of underlayment you need:

Temperate Climates: It is ok to use a premium, lighter weight, lower cost underlayment like TUFF90, that won't degrade over time and will provide excellent weather protection

Ultra Hot Climates: Use premium and thicker underlayment like TUFF150, that won’t degrade under prolonged heat and UV exposure.

Ultra Cold Climates: In areas prone to ice dams, consider underlayment with Ice and Water Shield for additional waterproofing around eaves and valleys.

Unusually Wet or Windy Areas: Opt for synthetic underlayment with superior water resistance and high tear strength to handle wind-driven rain or storms

Understand Local Building Codes and Regulations

Certain regions have specific requirements:

State Specific Regulations like Florida or Texas: Use underlayment that meet the requirements for certain states that require additional certification. TUFFDRY synthetic underlayment meets, meet Florida Building Code (FBC) and Texas Department of Insurance (TDI) standards for wind uplift and water intrusion.

Fire-Prone Areas: Check for Class A fire ratings (like TUFFDRY Underlayment) in areas where fire resistance is a priority.

Evaluate the Project’s Needs

New Construction: Use synthetic underlayment with long UV protection (e.g., TUFFDRY comes with UV protection for a full 180 days/6 months) to protect the roof deck during construction delays.

Re-Roofing Projects: Choose underlayment like TUFF90 that is lightweight, durable, and easy to install over existing materials.

Pick the Right TUFFDRY Product for Your Job

TUFF90

Ideal Underlayment, Built Specifically for Asphalt Shingles

TUFF150

Extra Strength Underlayment for under Heavier and More Abrasive Shingles and Aggressive Weather Regions

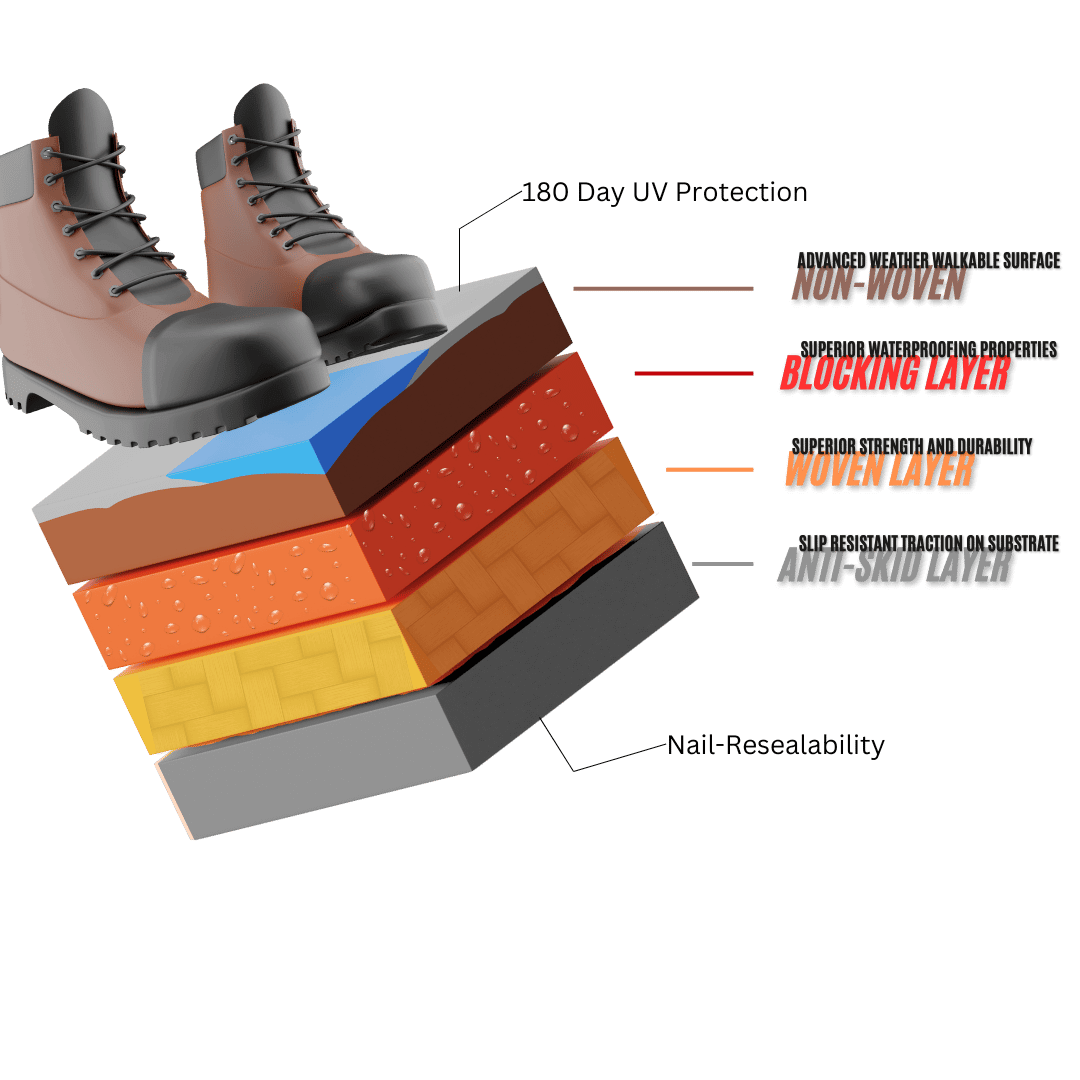

What Makes TUFFDRY, Premium ?

The magic of TUFFDRY synthetic underlayment lies in its multi-layered construction, which offers unmatched protection and strength.

Top Layer - Durability, UV Resistance & Walkability:

TUFFDRY synthetics are engineered to withstand the sun’s UV rays for up to 180 days, the premium construction holds up against normal foot traffic during installation and resists "pilling." The advanced walkable surface, designed to help keep roofers safe and stable while working on the roof. They grey color is specifically used to reduce heat for the workers during installation, while also minimizing sun reflection into their eyes.

2. Waterproofing Layer - Water Barrier:

Beneath the tough exterior is a highly efficient waterproofing layer. This is your primary defense against moisture. It acts like a raincoat, ensuring no water can seep through to the layers below, keeping your roof deck dry and preventing potential leaks. It also includes a Nail-Resealability feature that seals around nail holes to avoid water penetration.

3. Strength Layer - and Durability Over Time:

The third layer is all about strength. Synthetic underlayment incorporates woven materials that significantly enhance its tear resistance compared to felt paper. This woven layer will lay flat on the roof due to its precision manufacturing processes. making it easier to work with and more appealing on the roof to the home owners during installation. This layer is what makes it tough enough to handle extreme weather with reduced risk of ripping or tearing, even around nails or fasteners.

4. Anti-skid Layer - Safety & Sealing:

The final layer is all about function. It’s designed with a slip-resistant surface, additionally ensuring safety during installation by creating friction between the underlayment and the roof substrate, so the material does not slide around the roof during installation.

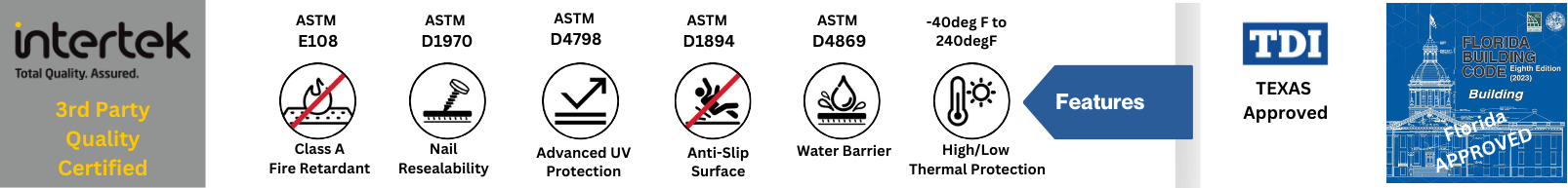

PRODUCT CERTIFICATIONS AND FEATURES

Our products meet or exceed ASTM standards and go through stringent 3rd party quality certification with InterTek, a process where only the best products can qualify.

TUFFDRY synthetic products are also Florida Building Code (FBC) and Texas Department of Insurance approved.

Why is Intertek Certification Important?

Third-Party Validation: Intertek acts as an impartial third party, providing an objective assessment of a product’s quality. This external validation is crucial because it removes any bias that might come from in-house testing or self-reporting. When a product is Intertek certified, you can trust that it has been evaluated thoroughly by experts who are not connected to the manufacturer.

Consistency and Reliability: Intertek certification is not a one-time event. Products must consistently meet high standards over time to maintain their certification. This ongoing scrutiny ensures that the quality of the product remains high and consistent, providing peace of mind for manufacturers and consumers alike.

Compliance with Industry Standards: Intertek’s certification process aligns with various industry standards and regulations. For roofing underlayment, this means that the product has been tested against the latest performance benchmarks and complies with necessary safety and quality regulations. This compliance helps ensure that the product will perform reliably under real-world conditions.

Consumer Confidence: For consumers and roofing professionals, Intertek certification serves as a mark of assurance. It indicates that the product has passed rigorous testing and meets the highest standards of quality. This can be particularly reassuring when choosing materials for critical applications like roofing, where performance and durability are essential.

PRODUCT FEATURES

AN UNDERLAYMENT FOR EVERY PROJECT:

Synthetic roofing underlayment is made from layers of non-woven and woven polypropylene and polyethylene plastic material that is nailed to the roof deck and sits under the decorative roofing layer. Its' purpose is to provide a layer of water protection to the roof system. Synthetic underlayment has replaced traditional felt/tar paper due to its extreme durability, resistance to mold, UV protection, water resistance, and ease of use during installation.

TUFFDRY offers an entire line of synthetic underlayment called TUFF, with various thicknesses and formulations to meet your specific needs. . Our products are created with a full 4 foot width to help reduce the installation effort, and minimize waste by reducing the number of overlapping seams required. Our products are created for consistency, reliability, durability and strength which your team will immediately appreciate as the product is light weight, lays flat on the roof and offers some of the best walkable surfaces available.

Ideal underlayment for under asphalt shingles

TUFF90

Ideal underlayment for under clay, slate, concrete and metal (Heavier Tiles with Higher Abrasion Strength)

TUFF150

Each TUFF product is certified with InterTek, a world class 3rd party organization that tests our products to provide our customers with unrivaled total quality assurance. They are also certified with the Florida Building Code.

Always reference your local building codes for final adherence of all building supplies

CUSTOMIZATIONS AVAILABLE

ONE OF THE BENEFITS OF WORKING DIRECTLY AND CLOSELY WITH OUR OWN FACTORY SOURCE, IS THAT WE CAN CONSIDER CUSTOM REQUESTS.

LOOKING FOR A DIFFERENT THICKNESS, WIDTH, CONSTRUCTION, FORMULATION ?

INTERESTED IN PUTTING YOUR BRAND NAME ON THE PRODUCT ?

LETS DISCUSS YOUR NEEDS